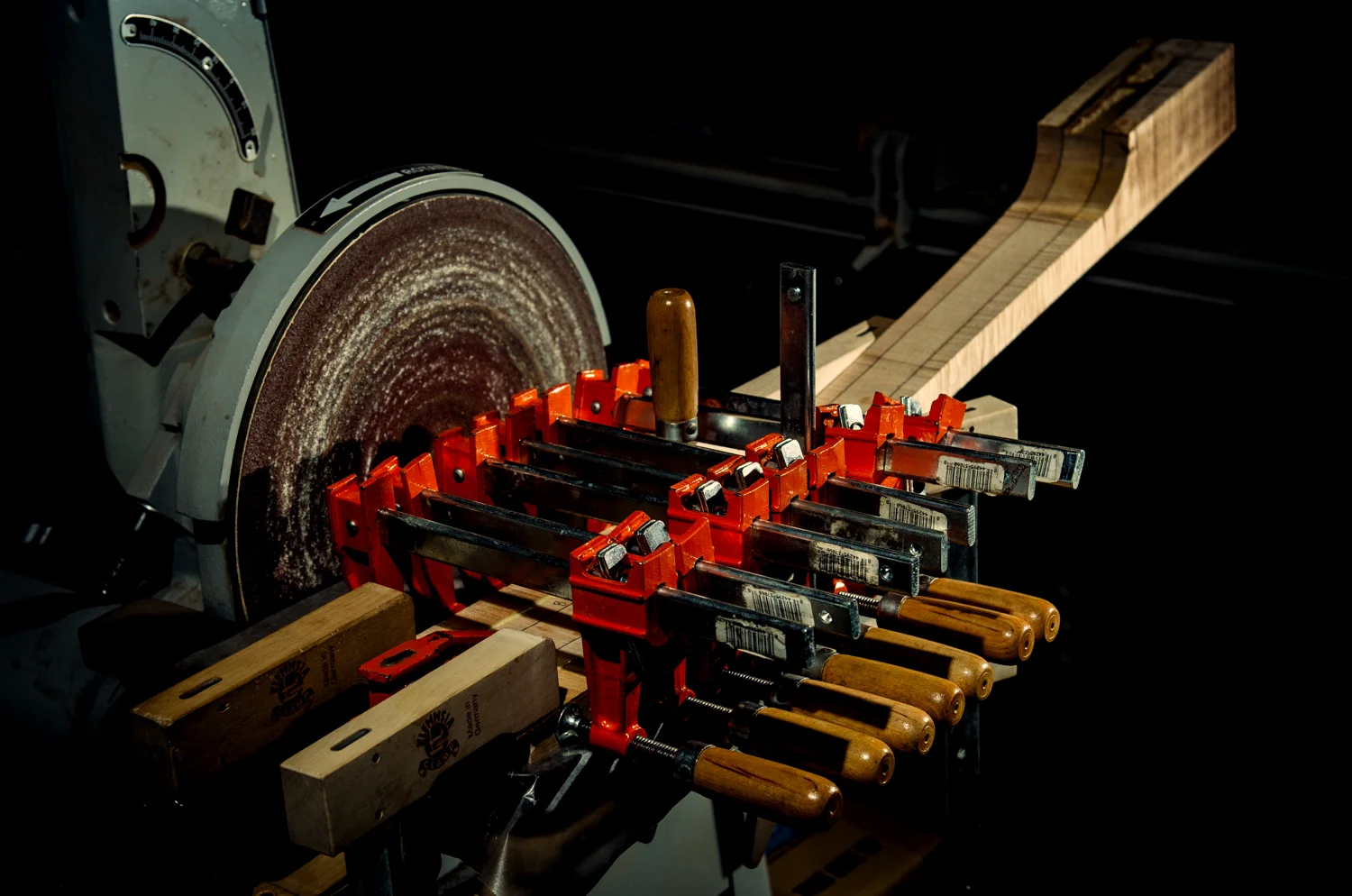

Neck prep :: using a drum sander to thickness pegheads.

Here I'm thicknessing the rear of the headstocks for Rogue 005 and Kalliope 001 before I laminate them. When I worked at Santa Cruz, they had a shop-made drum sander that works awesome for quickly thicknessing pegheads. I have always thought that I was going to have to build something similar for myself but have gotten around this task by using a Wagner Safe-T-Planer in my drill press. This time around I decided to see if I could use my new-ish drum sander. I was extremely pleased to find that the in-feed roller on the drum sander is easily removable. Much better results with this method in less time, but super dusty. I used a fan to attempt to direct some of the dust into the hood but I'll need to rig up something better next time.

Note: the Safe-T-Planer method works fairly well, but it requires more time to clean up the transition from head to neck.

![Peghead & body damage :: 2002 Tacoma Thunderchief CB28C [6.7 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1451420351155-RZZK9JC8X4SKJ8MD1R4A/image-asset.jpeg)