Equator Standard [Languedoc copy] :: set up and cleaned pots.

A couple years ago this guitar was in for new frets, new bone nut and brass saddles.

Chubbuck Guitars / Kevin Chubbuck, making & repairing guitars in an old building just north of Boston, Massachusetts.

![Equator Standard [Languedoc copy] :: set up and cleaned pots.A couple years ago this guitar was in for new frets, new bone nut and brass saddles.](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1407179902504-2Z8WN3N79FQAVMRQ33JK/image-asset.jpeg)

Equator Standard [Languedoc copy] :: set up and cleaned pots.

A couple years ago this guitar was in for new frets, new bone nut and brass saddles.

Back to building :: time to mill some red spruce brace stock and get these tops braced.

Charvel 625C NAT :: new bridge, saddle, pins, endpin jack and fret end dress.

The original bridge was failing and warped to the point that it needed to be replaced. A slightly larger bridge was fabricated to increase the gluing surface and to account for the wide saddle slot. The older Fishman undersaddle pickup is wide and thick (3/16” wide x 3/32” thick), so the slot had to be deeply routed to give enough room for the new compensated bone saddle. New slotted bone bridge pins replaced the broken / distorted plastic ones. The old endpin jack was shorted out so it was replaced with a new Switchcraft jack.

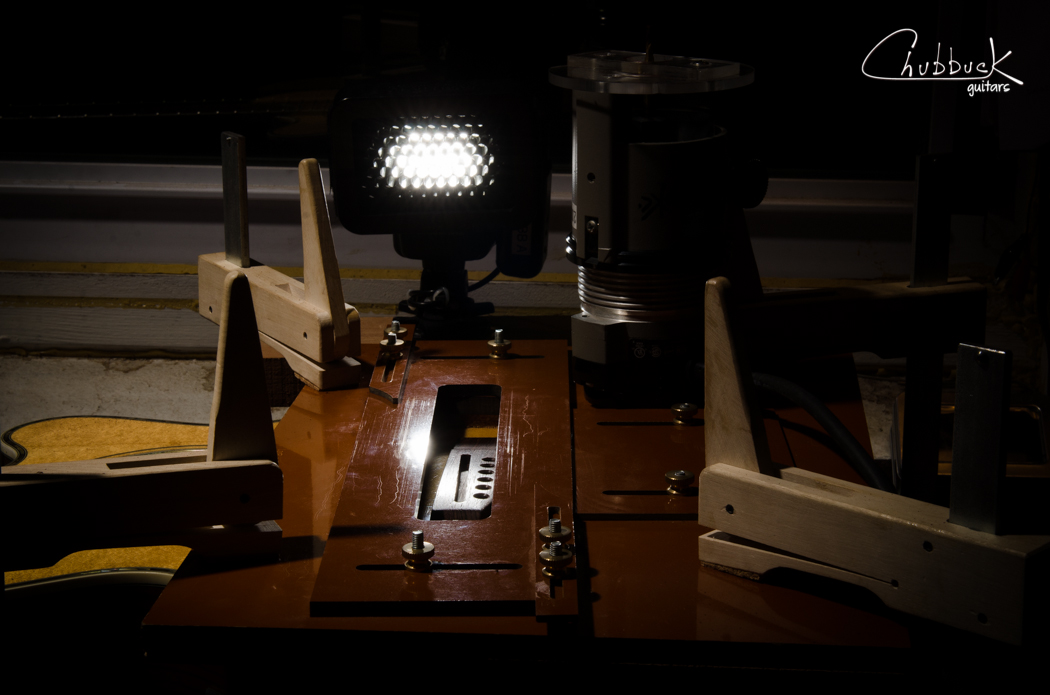

Charvel 625C :: routing the saddle slot.

The original bridge was warped and peeling from the top so a new one was fabricated. Here I’m routing the 3/16” wide saddle slot on the guitar to make sure the bottom of the slot is flat for the undersaddle pickup. The older Fishman pickup is wide and thick (3/16” wide x 3/32” tall) so I have to rout fairly deep to leave enough room for the new saddle.

Charvel 625C :: new bridge and setup.

The new bridge is glued on and here some loose fret ends are being clamped and glued down before I dress the sharp ends. Not an ideal solution but should save the customer money until he is ready for new frets.