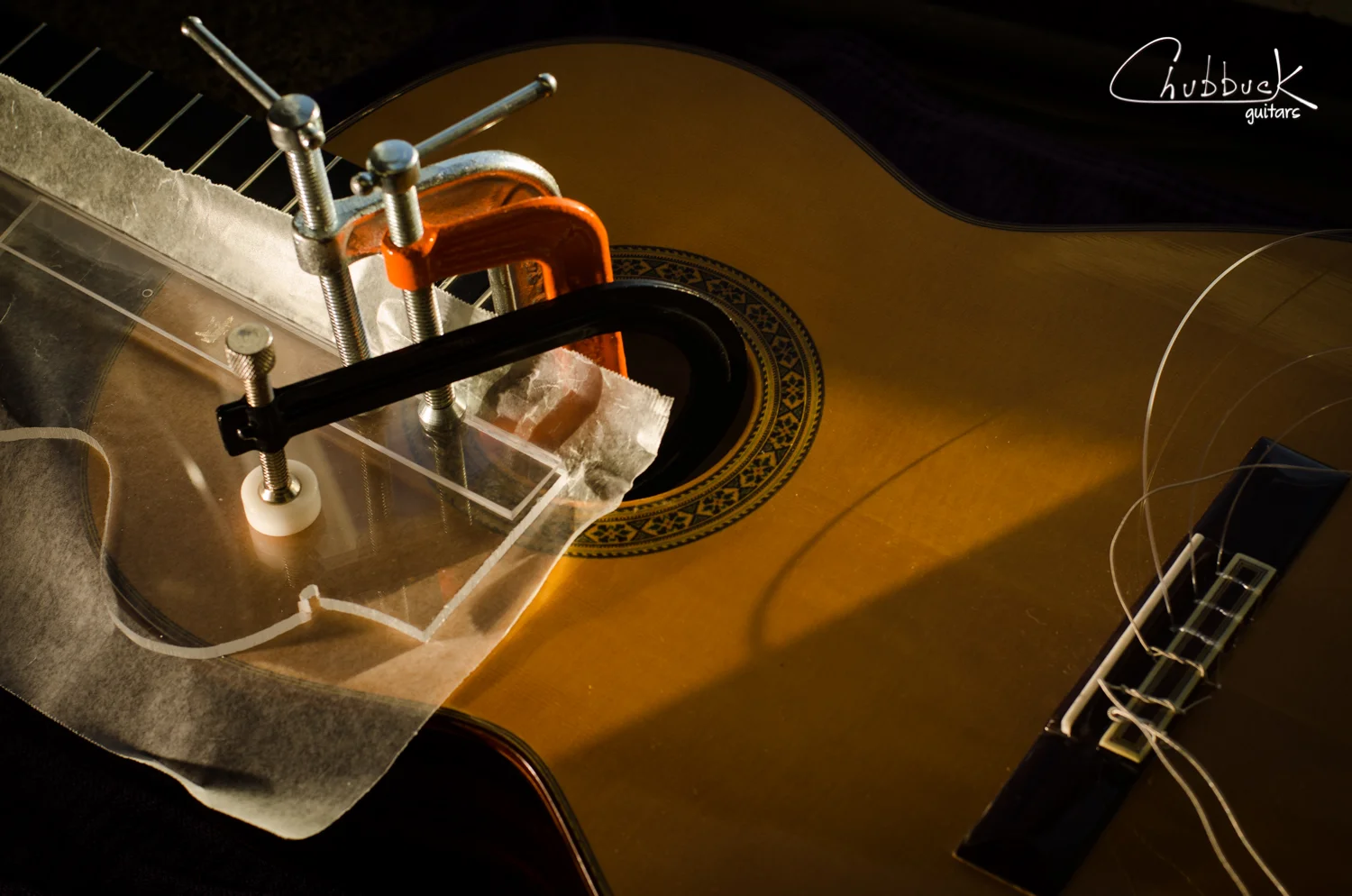

Sharp fret ends & center seam crack :: 2014 Maton EBG808C "Michael Fix" [4.3 lbs]

Another victim of a long, dry New England winter. The fret ends were sticking out from the unbound fingerboard and the top's center seam had opened up slightly just behind the bridge. The fret ends were dressed and the top crack humidified closed, glued and cleated along with a minor finish touch up.

![Sharp fret ends & center seam crack :: 2014 Maton EBG808C [4.3 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1430976793588-SYNKLBZXTHKG1ZZU12XW/image-asset.jpeg)

![Dried-out Fret Level :: Gitane DG-455 [4.0 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1430977447302-0BAIMRUH8OSS4D3AQ52R/image-asset.jpeg)

![Fingerboard extension top crack splint :: 2007 Pavan TP-30 [3.9 lbs]](https://images.squarespace-cdn.com/content/v1/53dfcee2e4b0c0da377c65c7/1430978517972-1TXXZD8ZW02EYV8J0IX6/image-asset.jpeg)